Sensorex Dissolved Oxygen Measurement

Dissolved Oxygen (DO) is the amount of oxygen dissolved in a unit of water. Oxygen gets into water by: diffusing within the surrounding air, aeration (turbulent movement), and as a waste product from plants through photosynthesis.

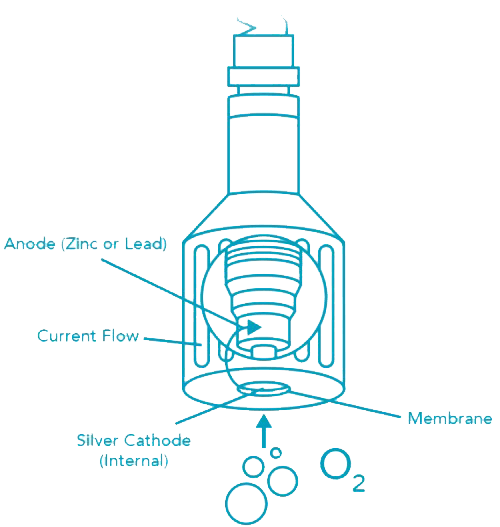

Galvanic DO sensors consist of two electrodes: an anode and cathode. Both of these electrodes are immersed in electrolytes (inside the sensor body). An oxygen permeable membrane separates the anode and cathode from the measured water.

Galvanic DO sensors consist of two electrodes: an anode and cathode. Both of these electrodes are immersed in electrolytes (inside the sensor body). An oxygen permeable membrane separates the anode and cathode from the measured water.

The permeable membrane allows oxygen from the sample water to diffuse into the sensor, where it is reduced at the cathode. This chemical reaction produces an electrical signal, which travels from the cathode to the anode and then into the dissolved oxygen measuring instrument. Consumption of oxygen at the cathode creates a pressure difference across the membrane that varies based on the partial pressure of oxygen in the sample. Therefore, as oxygen concentration increases, partial pressure and the rate of diffusion also increase, and the current to the instrument increases proportionally.

Why is Dissolved Oxygen Measurement Necessary?

For aquaculture, if the DO level falls too low then the fish will suffocate as a consequence. In a sewage treatment plant, bacteria will decompose the solids. If the DO level is too low, then the bacteria will die and the decomposition will cease; if the DO level is too high, then the energy will be wasted through the aeration of the water. In industrial applications, including boilers, the make-up water must have low DO levels in order to avoid corrosion and boiler scale build up.

Monitoring dissolved oxygen content is essential for ensuring process efficiency, because boiler scale build up inhibits heat transfer. A high DO level in water improves the taste of drinking water. However, high DO levels will increase corrosion in water plumbing and transport lines.

ODO8000 and ODO9000

Lumin-S Optical Dissolved Oxygen Sensors with Digital Communication

The Lumin-S optical dissolved oxygen sensor delivers reliable DO measurements over a long operating life. There are no membranes to replace, no electrolyte solutions to replenish, and no anodes to clean. Maintaining the sensor is as easy as replacing the optical sensing cap once every 1-2 years, and since all calibration data is stored on the cap, there’s no need to calibrate. This dissolved oxygen sensor outputs a Modbus/RS-485 digital signal for easy PLC integration.

- Reliable measurements: Optical sensor technology delivers accurate DO monitoring with no drift and no minimum flow

- Long operating life with minimal maintenance: No membranes, electrolyte solutions, or anodes – just replace the cap once every 1-2 years

- No calibration: All calibration data is stored on the cap for quick and easy startup

- Simple system integration: Use Modbus/RS-485 to integrate with a PLC or other control system

- One year limited warranty

DO1200

Galvanic Dissolved Oxygen Sensor

Our DO1200 galvanic dissolved oxygen sensors measure the oxygen content of water using an electrochemical measurement principle. Built in an economical but durable 12mm epoxy body, these sensors are suitable for portable or benchtop use. The DO1200 can also be installed inline for continuous monitoring applications by upgrading to a PTFE membrane cap. The sensor is compatible with our FC75P 3/4 inch in-line fitting for mounting into 3/4 inch FNPT threaded tees.

- Galvanic (electrochemical) measurement principle

- Replaceable membrane cap and fill solution

- 12mm durable epoxy body

- For benchtop, portable, or inline use

DO6400

Dissolved Oxygen Sensor with Digital Communication

The DO6400 series galvanic dissolved oxygen sensor delivers accurate measurements with very fast response time. Calibration is simple and only requires a single-point air calibration, and its large electrolyte reservoir decreases downtime due to maintenance. This dissolved oxygen sensor directly outputs a Millivolt, 4-20mA analog or MODBUS/RS485 digital signal scaled to the sensor range for easy PLC integration.

- Fast response time: Galvanic sensor technology delivers accurate dissolved oxygen monitoring

- Simple system integration: Uses direct Millivolt, 4-20mA analog or MODBUS/RS485 digital output signal to integrate with a PLC or other control system

- Input Voltage Options:

- 12V DC – MODBUS only

- 24V DC – 4-20mA & MODBUS

- Infrequent, easy maintenance: Large electrolyte reservoir facilitates long-term sensor deployment

- One year limited warranty

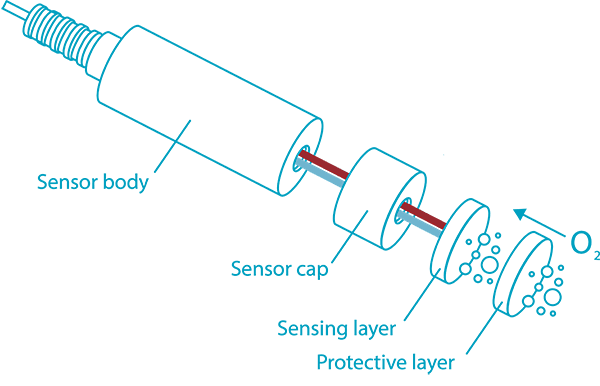

Optical dissolved oxygen sensors feature replaceable caps containing the sensing element: a special dye that will luminesce (glow red) when exposed to light of a particular wavelength. The dye is covered by an oxygen permeable paint layer, which allows oxygen molecules to interact with the dye, while protecting it from other sample constituents. Oxygen interferes with the dye’s luminescence (intensity and lifetime). The sensor emits light and measures the resultant luminescence with a photodiode. This reading is compared to a reference reading using light of a different wavelength. The measurement and reference values are compared to calculate dissolved oxygen in the sample.

Optical dissolved oxygen sensors feature replaceable caps containing the sensing element: a special dye that will luminesce (glow red) when exposed to light of a particular wavelength. The dye is covered by an oxygen permeable paint layer, which allows oxygen molecules to interact with the dye, while protecting it from other sample constituents. Oxygen interferes with the dye’s luminescence (intensity and lifetime). The sensor emits light and measures the resultant luminescence with a photodiode. This reading is compared to a reference reading using light of a different wavelength. The measurement and reference values are compared to calculate dissolved oxygen in the sample.