Hontzsch Flow Measuring Technology

Measuring technology for flow rate, mass flow rate and flow velocity

Hontzsch measuring instruments are applicable at high pressures up to 50 bar. They deliver precise measuring results even with smallest flow measuring velocities and lowest volume flows.

In sample gases such as ammonia, butadiene, hydrogen, LPG, natural gas, propane and many other media Höntzsch measuring instruments deliver exact values.

Their flow sensors are applied even under toughest circumstances such as strong pollution or dust pollution.

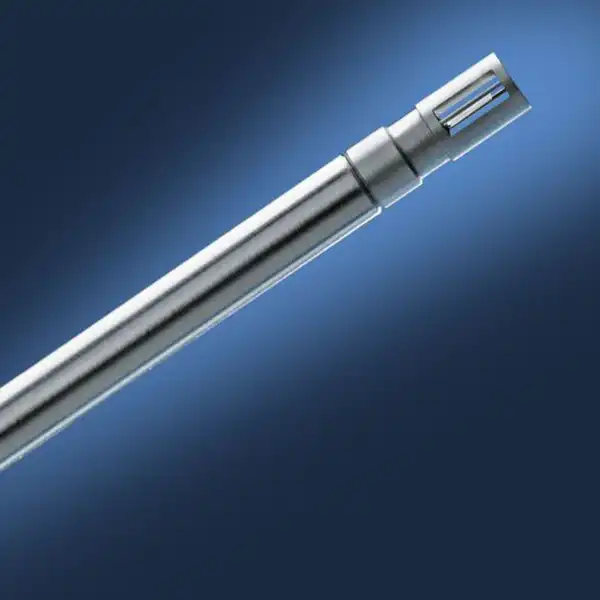

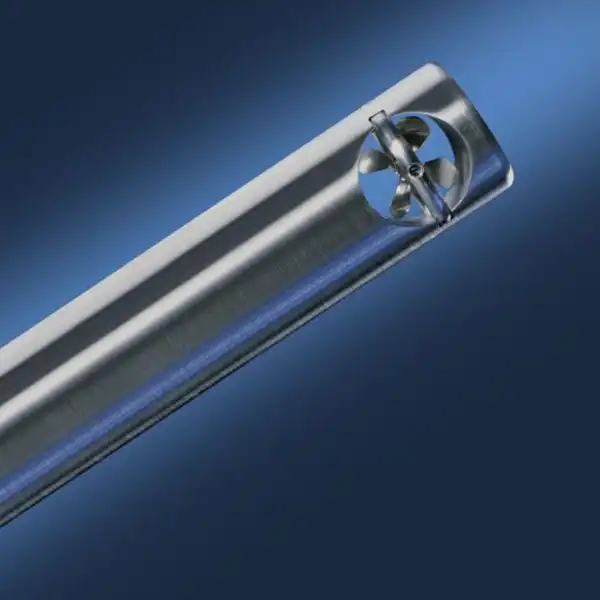

Vane Wheel FA

Flow rate and flow velocity in pipes and ducts, measuring flow profiles, aerodynamic research, measuring laminar flow, also at high gas temperatures, landfill gas, exhaust gas, flow rate and flow velocity in flowing waters.

Measurement is based on a vane wheel rotating at a speed proportional to the flow velocity of the fluid which surrounds it. The rotational speed is virtually independent of density, pressure and temperature of the medium. Vane wheel anemometers can be used in gases and liquids.

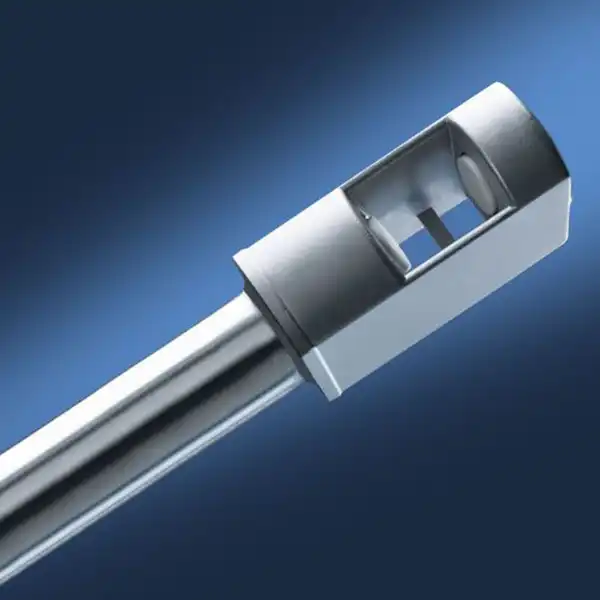

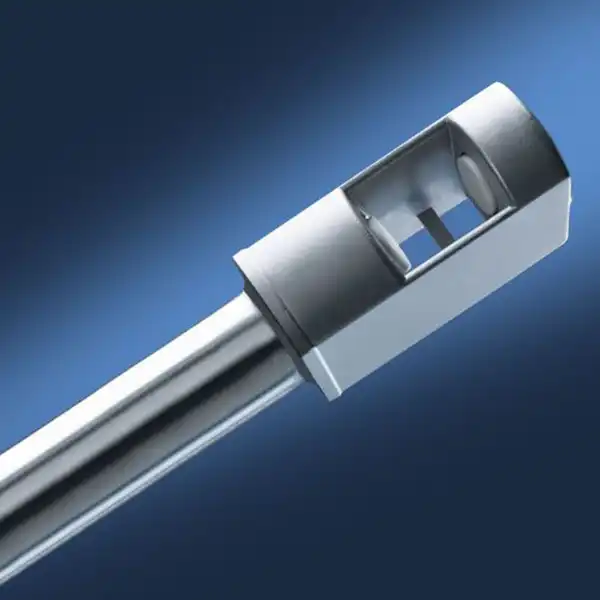

Vortex VA

Flow rate and flow velocity measurement in wet and/or particulate-laden gases, biogas or exhaust gas, also according to Clean Air Guidelines, (TA Luft). Flow rate measurement of sludge aeration air, sewage gas, landfill gas, water vapour and engine intake air on test stations. Flow velocity in climatic wind tunnels, diluted car exhaust gas and traffic tunnels.

Derived from the Kármán phenomenon of vortex shedding, this principle of measurement is based on vortices forming around a bluff body in the sensor head. Their shedding frequency is detected with the help of an ultrasonic field, thus allowing for precise measurement of flow velocity and flow rate, from just 0.5 m/s, of air/gases.

Advantages

- Flow rate measurements are to a large extent unaffected by changes in pressure, temperature, kinematic viscosity and gas composition. The great advantages of ultrasonic scanning of the flow velocity are the very low initial value of just 0.5 m/s and the wide measuring range!

- Vortex meters have high long-term stability, no moving parts and are resistant to aggressive gases. They still deliver exact results even when the flow is particle-laden or condensate forms. This means that vortex flowmeters are highly suited for biogas measurement or flow rate measurement in exhaust emissions. They deliver exact measuring results even in change of gas composition, particle laden flow or condensate formation.

- Sensing of rotational direction and with it recognition of the +/- direction of flow.

Thermal TA

Fixed and portable measurement of consumption quantity in compressed air and other clean gases; Measurement of laminar flow in clean rooms, under fan-filter-units; flow measurement in production facilities of the pharma-; food-processing- and semiconductor industry as well as flow-monitoring in glove boxes, isolators or sedimentation rate measurements in spray booths. Measurement of burner air and leakage flow; Monitoring of safety-relevant facilities – in aerospace as well as boats and ships.

The calorimetric measuring method is based on electrically heating a mechanically protected installed sensor element. Measure for flow velocity of air or gas, is the difference in temperature between the heated element and the medium. Thanks to Höntzsch’s high quality thermal flow sensors very low and high flow velocities, mass flow, standard flow rate of gases can be measured with only one sensor.

Standard flow rate and mass flow rate can even be measured under extreme circumstances with our calorimetric flow sensors!

Due to the principle of measurement operating temperature and pressure of the medium have no influence on the measuring results. Since it’s a calorimetric measuring method only property data and gas components are crucial.

Ultrasonic Flowmeter for Liquids

This principle of measurement is also referred to as the transit time difference method. For measuring the flow rate of liquids using this technique, ultrasonic pulses are sent and received simultaneously through the medium in the direction of flow and against it. The sensors work alternately as transmitter and receiver. The transit time of the acoustic signals filtered through the medium in the direction of flow is shorter than that against it. The difference in transit time Δt is measured and can be used to calculate the average flow velocity of liquids filtering through the acoustic path. After measuring the flow velocity and with the pipe cross-sectional area, volumetric flow can be calculated.

- installation without process interruption or shut-down

- easy and cost-effective assembly

- light-weight ergonomic design

- ideal for use in maintenance areas and commissioning

- testing fixed measuring equipment

Vane wheel flow sensors as insertion probes are suited for fixed and portable flow measurements in gases and liquids/water as well as Ex-applications (ATEX, CSA). Flow sensors as probes can be used in tubes with an inside diameter of 40mm. It is mounted with a if necessary pressure resistant probe guide piece. Alternatively flow sensors can be handheld in free currents, for gases, water and in liquids or for measurement of fluid flow. Probe extensions are for the flow sensor to enter deeper into the medium for example water or to measure gas emissions in chimneys and tunnels in burner installations in case the standard length isn't sufficient.

Vane wheel flow sensors as insertion probes are suited for fixed and portable flow measurements in gases and liquids/water as well as Ex-applications (ATEX, CSA). Flow sensors as probes can be used in tubes with an inside diameter of 40mm. It is mounted with a if necessary pressure resistant probe guide piece. Alternatively flow sensors can be handheld in free currents, for gases, water and in liquids or for measurement of fluid flow. Probe extensions are for the flow sensor to enter deeper into the medium for example water or to measure gas emissions in chimneys and tunnels in burner installations in case the standard length isn't sufficient. Vane wheel measuring tubes are designed for fixed applications in pipelines or ducts. Installation is direct and irrespective of positioning. They are ideally suited for measuring low rates of gas flow in clean gases, briefly also in a particle-laden medium, and have inside diameters ranging from 9.7 to 150 mm. Measuring tubes receive an accurate volumetric calibration. Furthermore, they excel thanks to their marginal pressure loss and high turndown ratio 1:80. Connection is via flange, mechanical joint, screwed fittings, nipple, etc.

Vane wheel measuring tubes are designed for fixed applications in pipelines or ducts. Installation is direct and irrespective of positioning. They are ideally suited for measuring low rates of gas flow in clean gases, briefly also in a particle-laden medium, and have inside diameters ranging from 9.7 to 150 mm. Measuring tubes receive an accurate volumetric calibration. Furthermore, they excel thanks to their marginal pressure loss and high turndown ratio 1:80. Connection is via flange, mechanical joint, screwed fittings, nipple, etc. Transducers and evaluation units for fixed applications with vane wheel sensors FA and measuring tubes FA Di transform the sensor signal into a 4-20 mA or 0-10 V signal. In addition, they provide quantity pulses, limit values or flow direction.

Transducers and evaluation units for fixed applications with vane wheel sensors FA and measuring tubes FA Di transform the sensor signal into a 4-20 mA or 0-10 V signal. In addition, they provide quantity pulses, limit values or flow direction.